What is Solar Cable/Wire?

A solar cable/wire is a specialized electrical conductor designed to transmit electrical energy in photovoltaic (PV) systems, connecting solar panels to inverters, charge controllers, and other components. Engineered to withstand harsh outdoor environments, it ensures safe and efficient power transfer in solar energy applications.

Types of Solar Cable

1. PV Cable (Photovoltaic Cable)

• Key Features: PV cables are constructed with materials that offer excellent resistance to ultraviolet (UV) radiation, are flame-retardant, and are highly weatherproof. Insulation materials such as cross-linked polyethylene (XLPE) or ethylene-propylene-diene-monomer (EPDM) are commonly used. These properties make PV cables ideal for long-term outdoor use, protecting them from the damaging effects of sunlight, rain, and other environmental factors.

• Voltage Rating: In modern solar arrays, which often operate at high voltages, PV cables are typically rated for 1,000V DC or 1,500V DC. This high voltage rating enables them to handle the electrical requirements of large-scale solar installations, ensuring stable and reliable power transmission.

• Temperature Resistance: They can function in extreme temperature ranges, from as low as -40°C to as high as +90°C or even higher. This wide temperature tolerance allows PV cables to be used in various climates around the world, from cold polar regions to hot deserts.

2. Solar Panel Interconnect Cables

• Function: These cables are used to connect individual solar panels in series or parallel within a PV array. By establishing these connections, the solar panels can work together to generate the desired electrical output. For example, in a large solar farm, thousands of solar panels are interconnected using these cables to form a cohesive power - generating system.

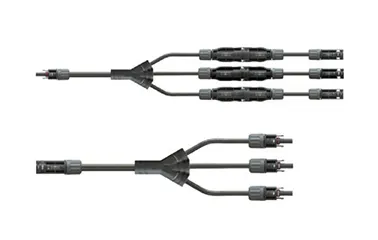

• Design: Solar panel interconnect cables are often pre - fitted with MC4 connectors (or similar types). These connectors are designed to be quick to install and are highly waterproof. The use of such connectors reduces installation time significantly and also ensures a reliable and secure connection between the panels, minimizing the risk of electrical failures due to water ingress.

3. DC to AC Conversion Cables

• Purpose: DC to AC conversion cables are responsible for linking inverters, which convert direct current (DC) generated by solar panels into alternating current (AC), to the electrical distribution system. This connection is essential as most household and grid - connected electrical systems operate on AC power.

• Specification: To protect against physical damage during routing through buildings or conduit, these cables may come in armored or sheathed variants. The additional protection ensures that the cables can withstand mechanical stress, such as being bent, crushed, or scratched during installation and over their lifespan.

4. Battery Connection Cables

• Application: In off - grid or hybrid solar systems, battery connection cables are used to connect solar arrays to batteries for energy storage. These systems store excess electricity generated during the day for use during periods when the sun is not shining, such as at night or on cloudy days.

• Requirement: Battery connection cables need to have a high - current capacity to handle the charging and discharging cycles efficiently. To prevent over - current situations that could damage the batteries or cause electrical hazards, these cables are often paired with fuses or other circuit protection devices.

What is the Use of Solar Cable/Wire

1. Core Function in Solar Systems

Solar cables and wires are the lifelines of solar energy systems. Their primary function is to transmit the direct current (DC) generated by solar panels to inverters. Once the DC power reaches the inverters, it is converted into alternating current (AC), which can then be used for household purposes or fed into the electrical grid. Additionally, these cables facilitate connections within solar panel strings, allowing the panels to work in unison. They also connect inverters to batteries in systems with energy storage capabilities and from inverters to the main electrical panel, ensuring a seamless flow of power throughout the system.

2. Environmental Durability

Unlike standard electrical wires, solar cables are specifically engineered to resist UV radiation, moisture, ozone, and temperature fluctuations. These are common challenges in outdoor PV installations, where cables are constantly exposed to the elements. The ability of solar cables to withstand these environmental factors minimizes maintenance requirements. For example, in a coastal area where there is high humidity and salt - laden air, solar cables with proper corrosion - resistant properties can continue to function optimally without frequent replacements. This durability also extends the lifespan of the entire solar system, making it a more cost - effective long - term investment.

3. Safety and Compliance

Certified solar cables adhere to international standards such as IEC 60227 - 3 and UL 4703. These standards ensure fire safety, chemical resistance, and proper insulation. By using compliant cables, the risks of electrical faults, such as short - circuits or electrical fires, are significantly reduced. In a large - scale solar power plant, compliance with these standards is not only a matter of safety but also a regulatory requirement. Non - compliant cables can lead to system failures, financial losses, and potential safety hazards.

4. Efficiency Optimization

Proper cable sizing is crucial for minimizing energy loss in solar systems. Cable sizing is determined based on factors such as the amount of current flowing through the cable, the allowable voltage drop, and the distance the power needs to be transmitted. Using undersized wires can lead to significant voltage drops, which in turn reduces the overall efficiency of the solar system. On the other hand, using oversized cables can increase costs unnecessarily without providing a proportional increase in performance. For a small rooftop solar installation, accurate cable sizing can ensure that the maximum amount of power generated by the panels is utilized, rather than being lost in the transmission process.

Recommendations for Selection

• Check Ratings: It is essential to ensure that the cables you choose meet the voltage, current, and temperature requirements of your specific PV system. Different solar installations have varying electrical demands, and using cables with incorrect ratings can lead to performance issues or even damage to the system. For example, a large commercial solar installation may require cables with a higher current - carrying capacity compared to a small residential setup.

• Look for Certifications: Prioritize cables with regional certifications. In Europe, TÜV - certified cables are highly regarded, while in North America, UL - certified cables are preferred. These certifications are a testament to the quality and compliance of the cables, giving you peace of mind that you are using a reliable product.

• Consider Installation Environment: The installation environment plays a significant role in cable selection. In harsh climates, such as areas with extreme cold or heat, armored cables can provide additional protection. In coastal areas, where salt corrosion is a concern, cables with specialized sheathing can be used. Similarly, in installations with high mechanical stress, such as industrial settings, cables with robust construction should be chosen.

By carefully selecting the right solar cables and following proper installation practices, users can enhance the safety, efficiency, and longevity of their solar energy systems. Whether you are installing a small solar panel system on your rooftop or a large - scale solar farm, choosing the appropriate cables is a critical step in ensuring the success of your solar energy venture.