For solar project investors and installers, certified solar wire are not an optional "cost upgrade," but an absolute necessity to ensure safety and avoid irreversible losses. Let's look at TÜV SÜD's 2026 photovoltaic system failure statistics: 12% of safety incidents can be traced back to substandard cables or poor connections, and uncertified products are the culprit in 70% of these failures. Choosing Suntree certified solar cables means you automatically comply with international standards such as EN50618 and UL4703. This reduces power loss during transmission to just 1.2% and eliminates safety risks from the outset.

An Invisible "Safety Shield" Against Compliance Risks

Certification is more than just a label on a product; it proves that the solar wire has passed rigorous testing under extreme conditions. What about uncertified cables? They often cut corners—reducing conductor purity and using cheap insulation materials. The result? The sheath becomes brittle under strong UV radiation, or overheats when humidity increases. We once conducted a comparative test: Suntree's UL4703 certified cable versus a random uncertified cable. After 1000 hours of UV exposure, the uncertified cable's sheath had deteriorated by 30%. And Suntree's cable? It maintained 98% structural integrity—the difference is clear.

Every photovoltaic cable in the Suntree series has dual certification from TÜV Rheinland and UL, and third-party testing confirms a 100% compliance rate. This is significant for overseas projects—it means smooth inspections and no rework. For example, a high-altitude photovoltaic project in Southeast Asia. After switching to Suntree's certified cables, they passed local inspections on the first try and saved 12% in additional rework costs. This was a wise decision.

The Core Logic of Long-Term Safety

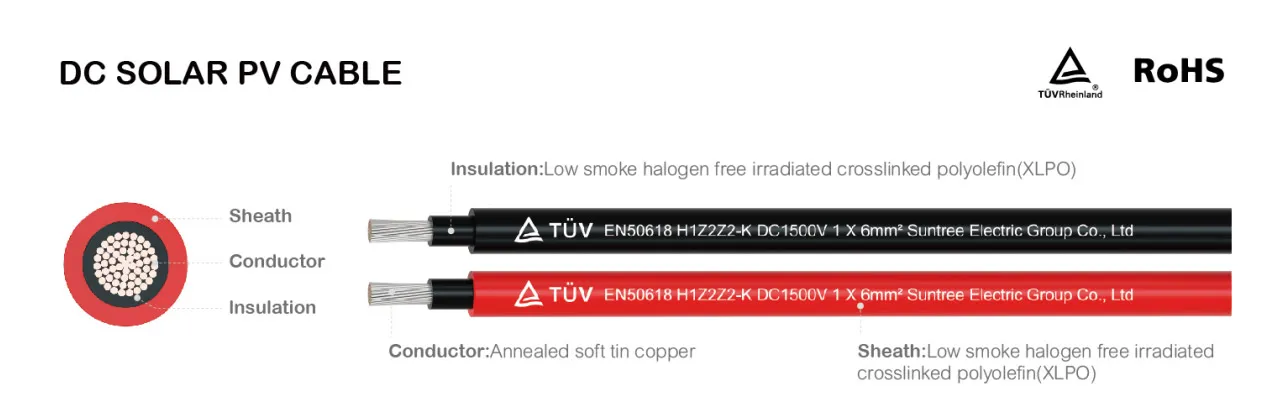

When it comes to the safety of solar wire, details matter—specifically, materials and workmanship. Suntree certified wires use 99.99% high-purity oxygen-free copper. Compared to ordinary copper, this reduces DC resistance by 3%, and for every 0.001Ω/km reduction in resistance, power loss is reduced by 0.5%. In addition, Suntree uses low-smoke, halogen-free insulation materials that comply with EU REACH standards, meaning they do not release toxic fumes even when burning, and the smoke density is less than 50%. This is crucial for rooftop installations or residential solar projects, as personal safety is always paramount.

On the other hand, uncertified wires often use recycled copper containing impurities. In high-temperature tests, their failure rate is 5 times higher than Suntree wires. Remember that desert photovoltaic project in the Middle East? It caught fire due to overheating of uncertified wires. They later replaced them with Suntree's weather-resistant cables, and the system has been running stably for 3 years without any overheating problems. This is the difference that high-quality materials make.

Safety Assurance for Different Scenarios

No two solar projects are exactly alike. High altitude, coastal humidity, desert sandstorms – each scenario requires solar wires tailored to the environment. This is where Suntree excels – they specialize in providing customized solutions, creating certified photovoltaic cables suitable for specific applications. For projects above 4500 meters, they adjust the conductor resistance to cope with low atmospheric pressure environments, ensuring 99.8% stability. For coastal areas, they use salt-mist resistant insulation materials to prevent corrosion from seawater vapor.

A distributed photovoltaic power plant cluster in Europe chose Suntree's customized flame-retardant wires. They successfully passed local fire inspections and are still operating well after three years without any failures. Furthermore, Suntree's technical team provides on-site installation guidance to ensure the wires perform optimally. This is not just a product, but a "product + service" safety assurance system.

Ensuring the Lifespan of Your Solar System

Solar systems are designed to last 25 years – therefore, the wires, as the "blood vessels" of the system, need to be equally durable. Suntree provides a 5-year warranty for its certified solar wires, with a lifespan of up to 25 years, matching the lifespan of your photovoltaic modules. This significantly reduces long-term maintenance costs. Furthermore, every Suntree wire has a unique electronic identifier, allowing for full traceability from manufacturing to installation.

Don't let uncertified wires turn your solar investment into a ticking time bomb. Learn more about Suntree's certified photovoltaic cable series today, and contact them for free customized solutions for your project.